Galvanizing at 120 gms per sq mtr.

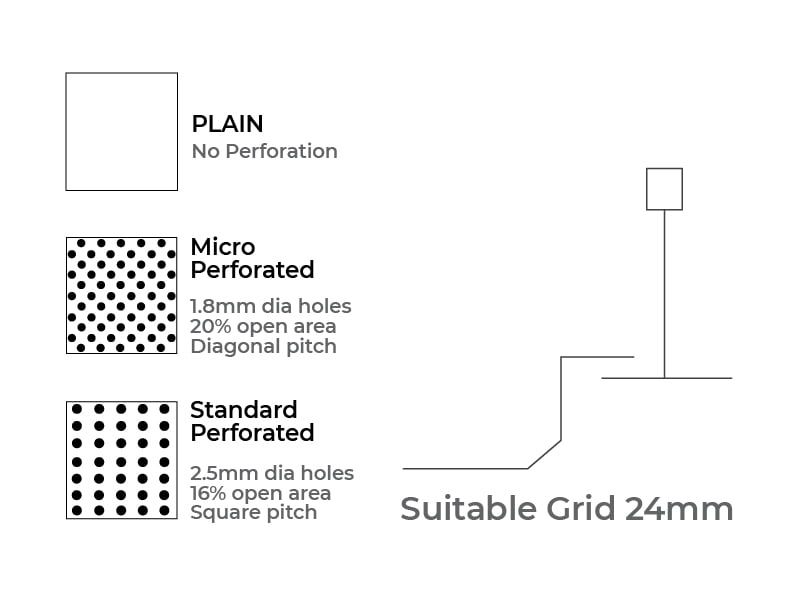

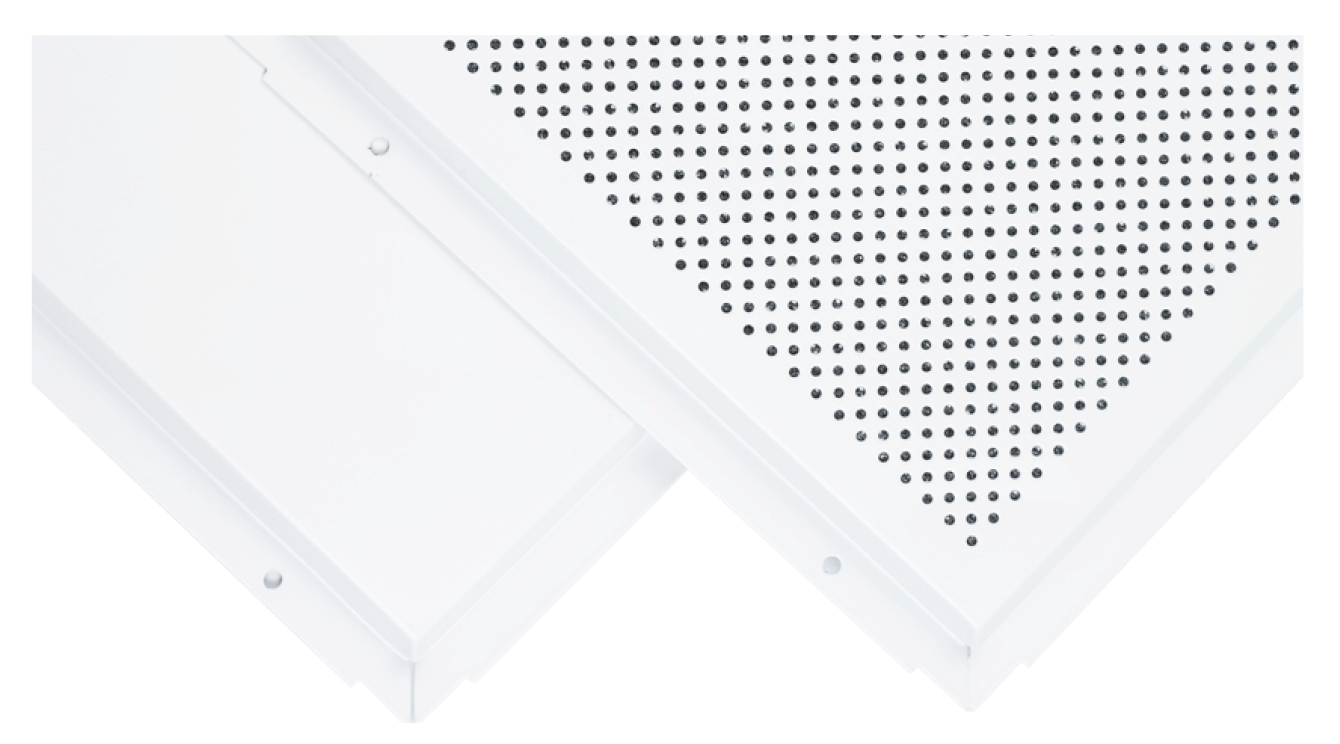

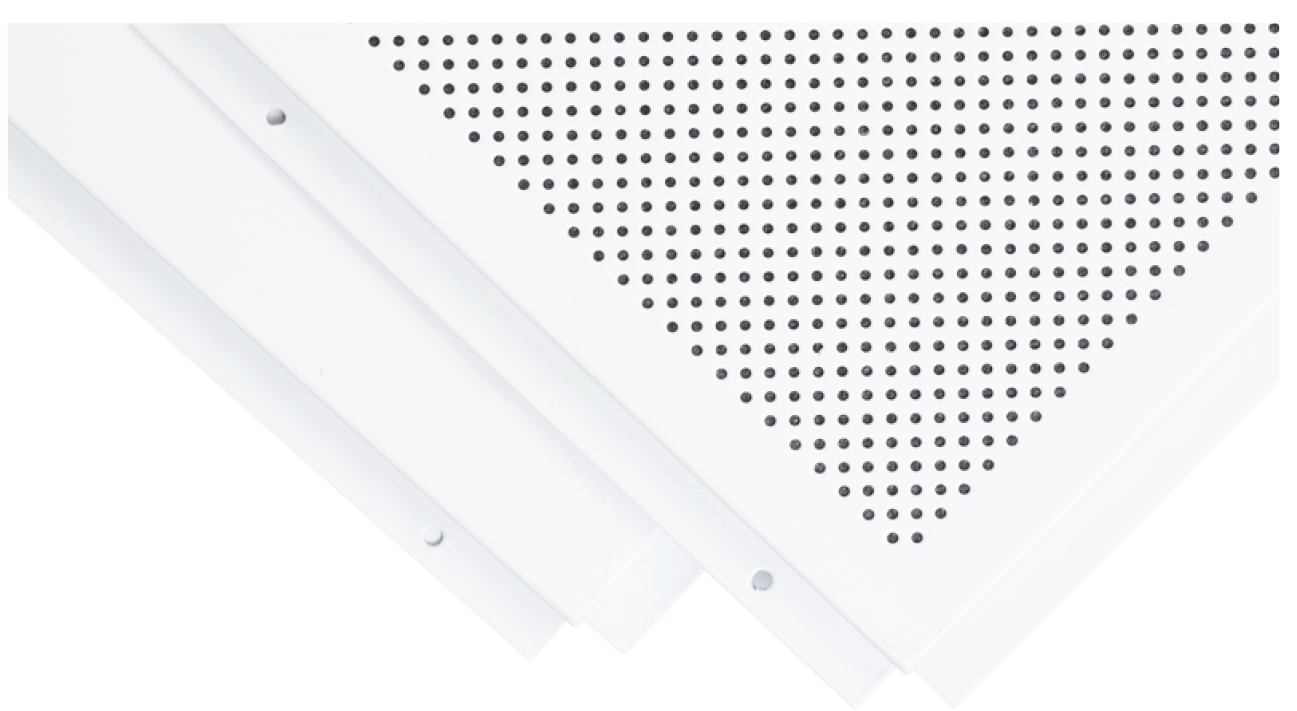

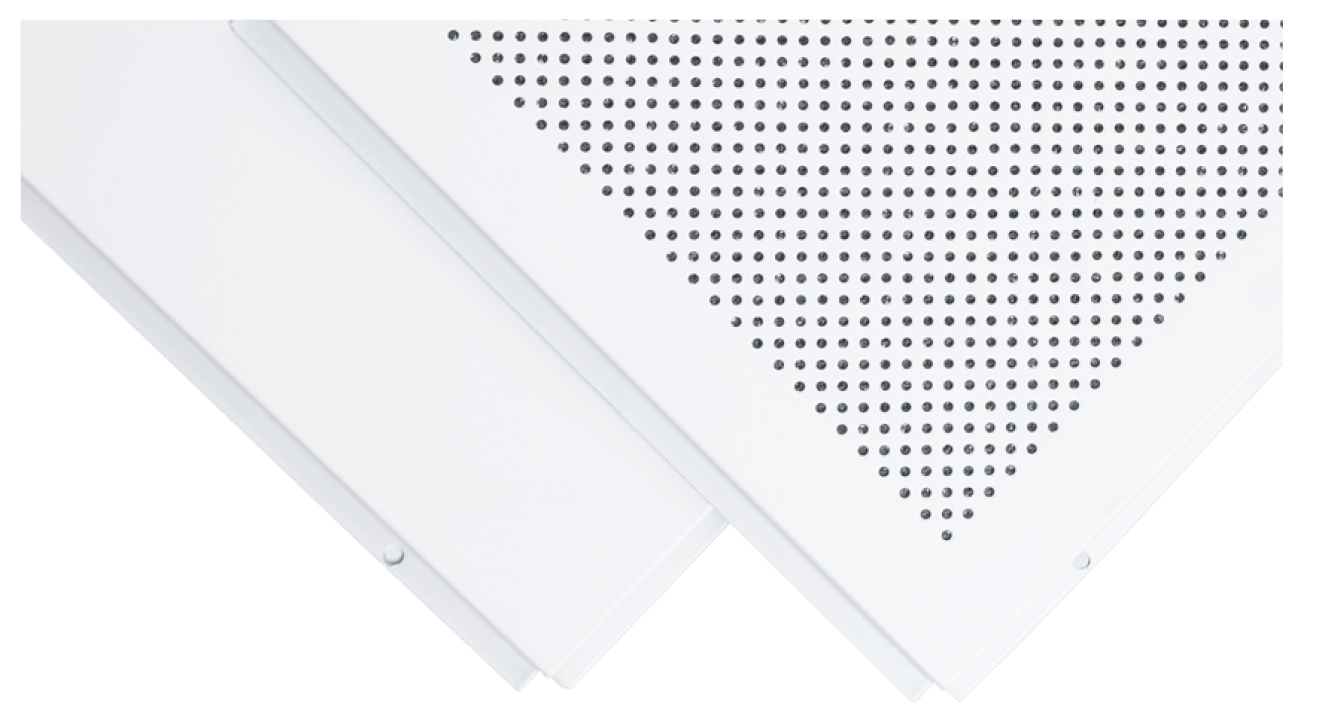

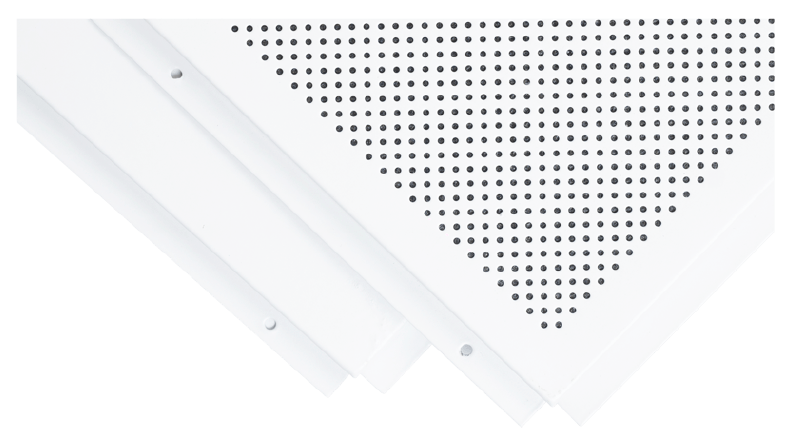

Diamond Lay In Metal Ceiling Tiles

Diamond Lay In Metal Ceiling Tiles

Diamond Metal Ceilings Tiles are made with GI coil Galvanized at 120 GSM/SQM and Powder coated at minimum 80 Microns.

![]()

Powder Coated at 80 Microns

NRC >= 0.5

Lay In Metal Ceiling Tiles - Powder Coated

Technical Specifications for Diamond Lay In Metal Ceiling Tiles - Powder Coated

| Material | G.I. Coil |

| Galvanized | 120GSM/SQM |

| Electro Statically Polyester Powder Coated | 80 Microns Minimum |

| Color | Global White |

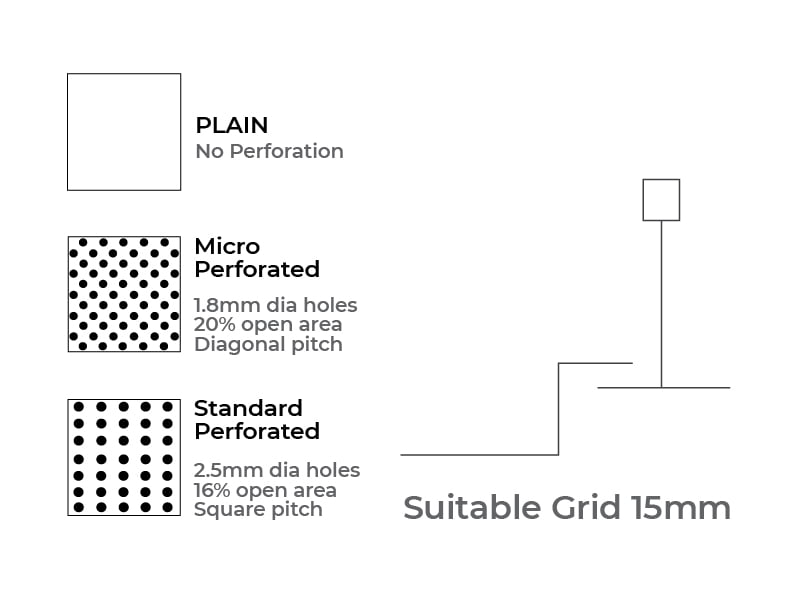

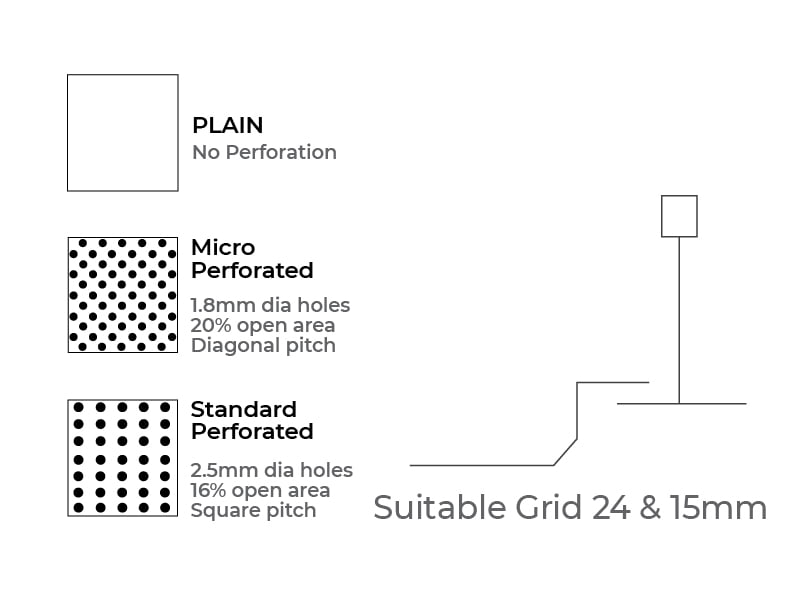

| Size | 595mm X 595mm |

| Thickness | 0.5 mm |

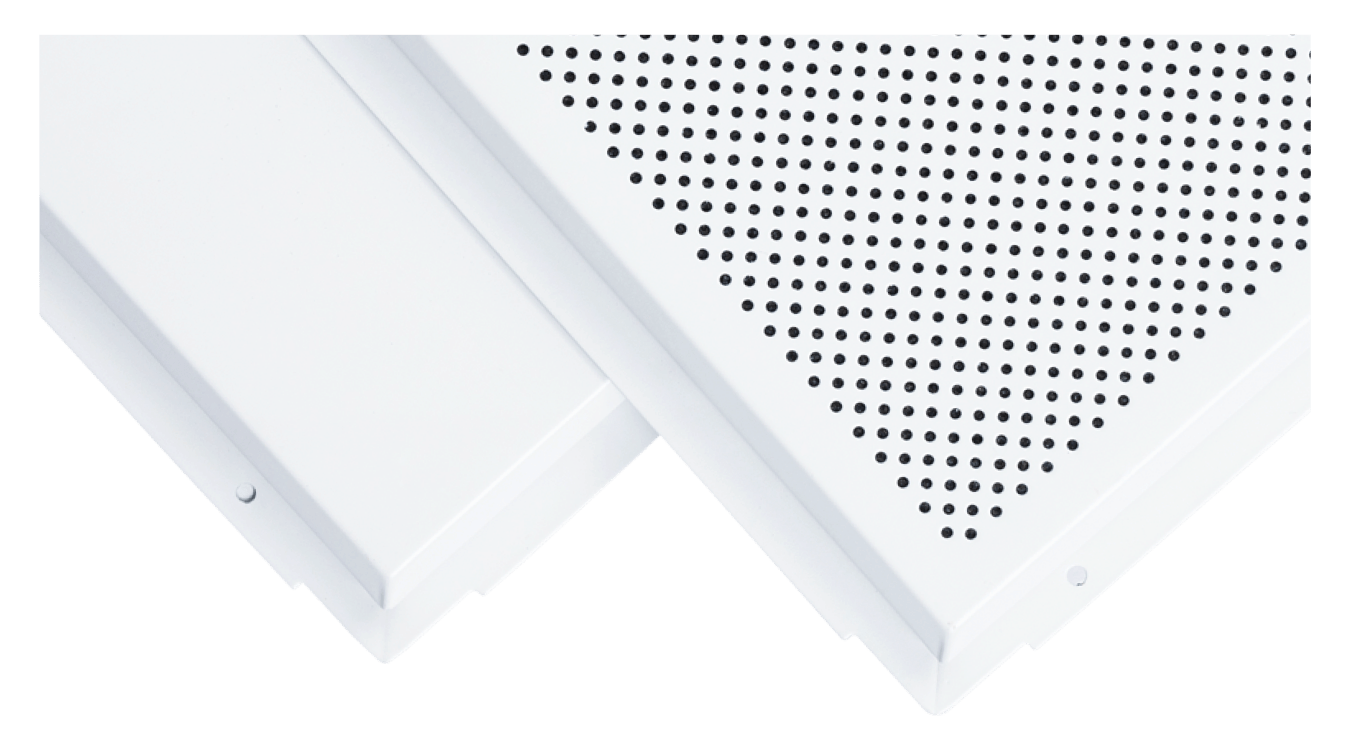

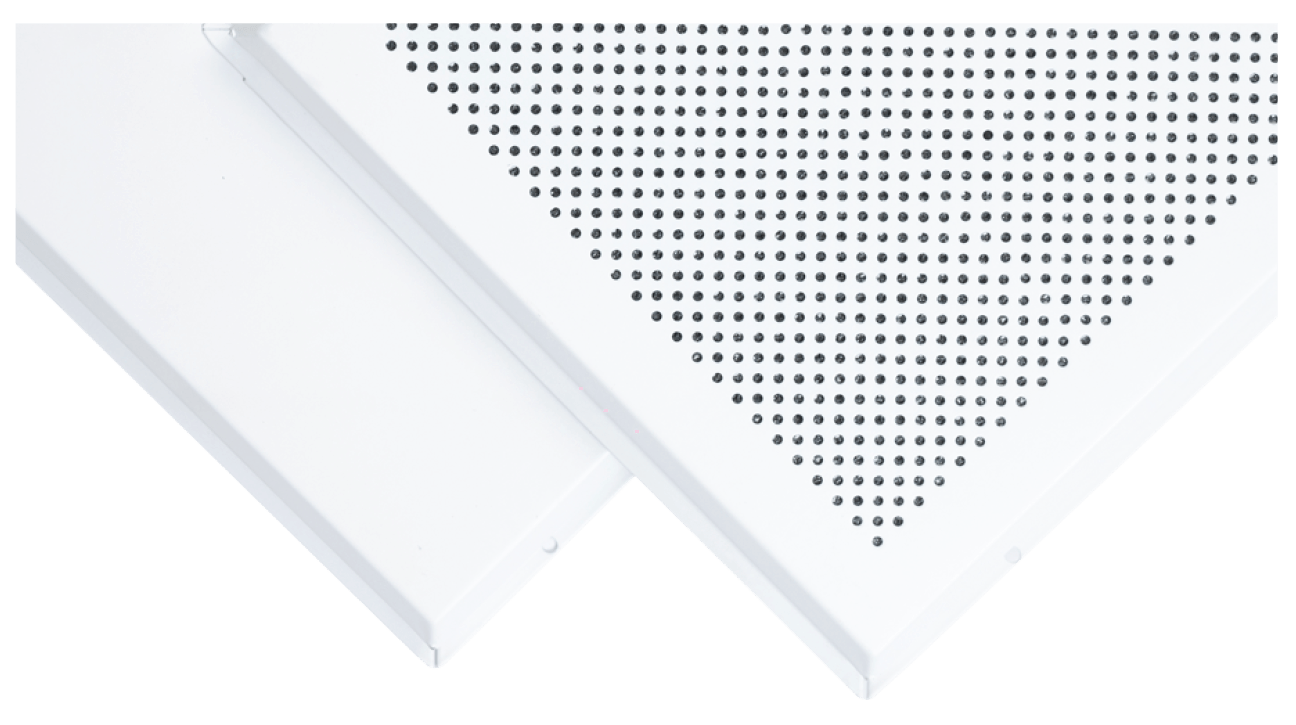

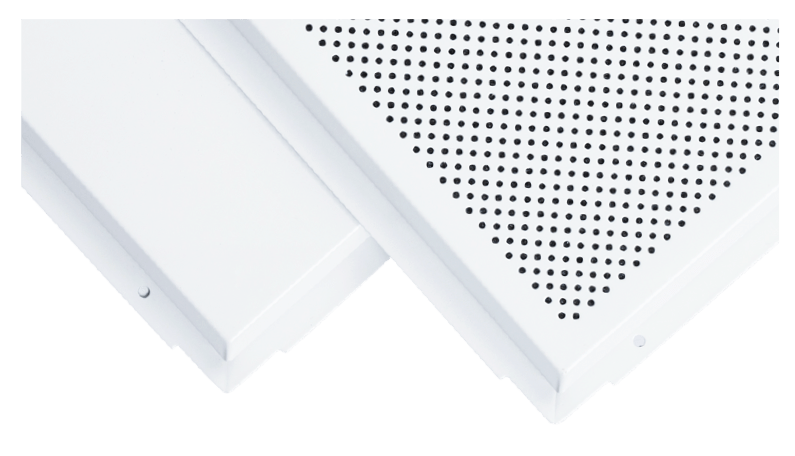

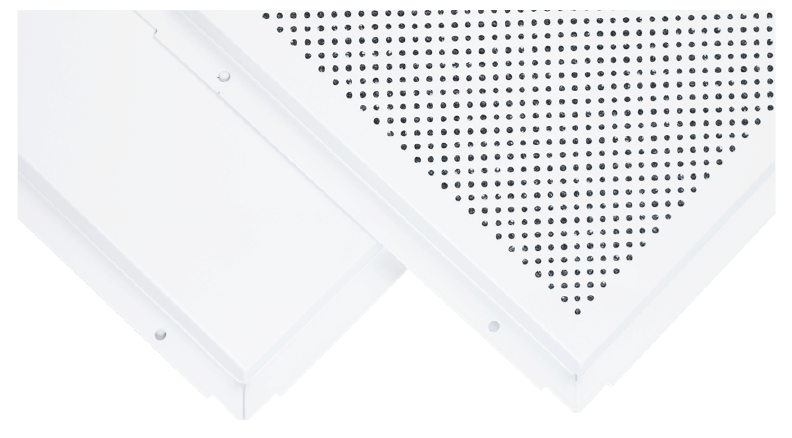

| Drop | 8mm 12mm |

| Edge Construction | Tegular/Micro Tegular/ Bevelled/Deep Bevelled |

| Light Reflectance | 0.85 – 0.90 |

| Humidity Resistance(RH) | 99% |

| Non Combustibility | BS 467 PART 6 &7 |

| NRC | ≥ 0.5 |

Technical Specifications for Diamond Lay In Metal Ceiling Tiles - Color Coated

| Material | P.P.G.I. Coil |

| Galvanized | 120GSM/SQM |

| Color | RAL 9003, 9002, 9010 |

| Size | 595mm X 595mm |

| Thickness | 0.5 mm |

| Drop | 8mm 12mm |

| Edge Construction | Tegular / Micro Tegular / Bevelled / Deep Bevelled |

| Light Reflectance | 0.85 – 0.90 |

| Non Combustibility | BS 467 PART 6 & 7 |

| Humidity Resistance(RH) | 99% |

| NRC | ≥ 0.5 |

Green Product/ Fire Retardant

Diamond Metal Ceiling Tiles, a creative concept

Salient Features

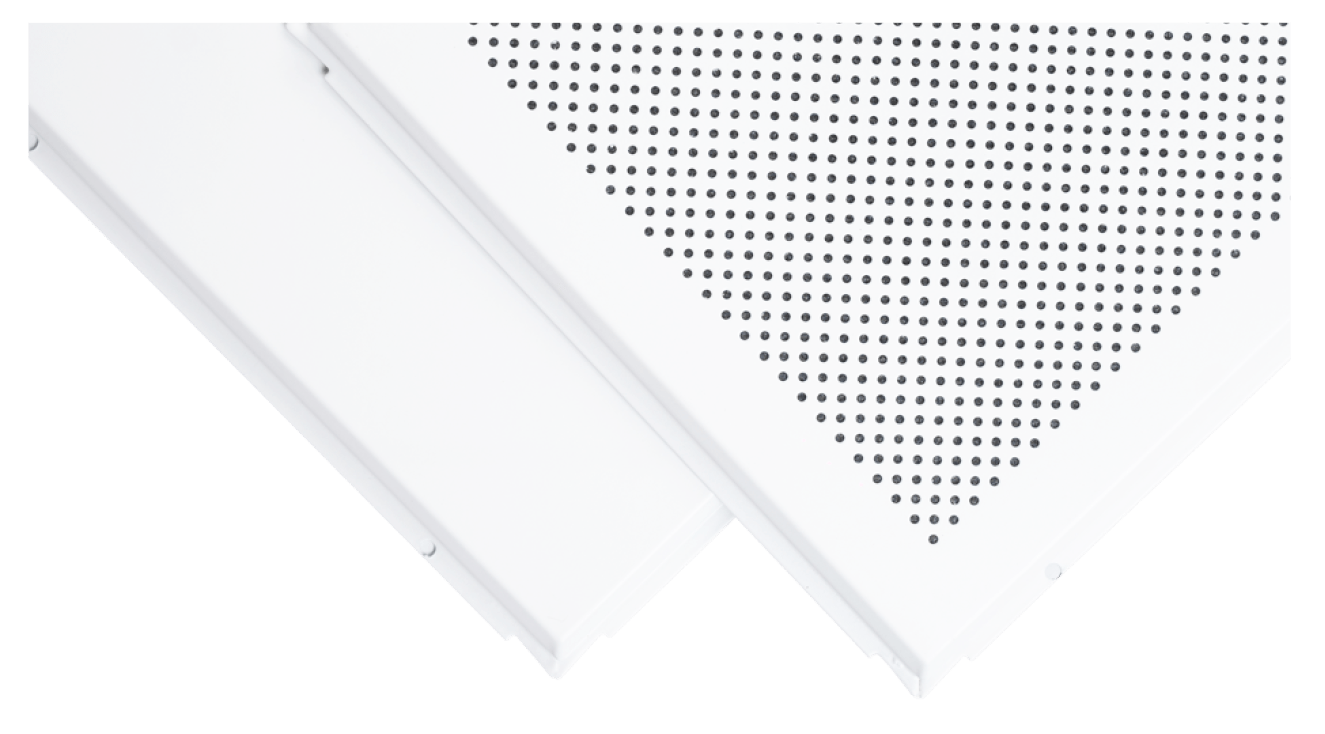

Diamond Metal Ceiling Tiles are Moisture Resistant and strong under high humid conditions.

- Contemporary Design

- Water Resistant

- Non-combustible

- Cost Effective

- Certified

- Press Formed Single Piece

- Asbestos Free

- Superior Light Reflectance

- Good Acoustic Perfomance

Advantages

Diamond Metal Ceiling Tiles are easy and convenient to install/fix. Recommended to be installed with Diamond Ceiling Grid.

- Airports

- Hospitals

- Super Markets

- Offices & Commercial Buildings

- Retail & Departmental Stores

- Educational Institutions

- Transport Terminals