Central Public Works Department under Ministry of Urban Development is one of the oldest Central Government Department, providing engineering excellence over 150 years in the construction filed.

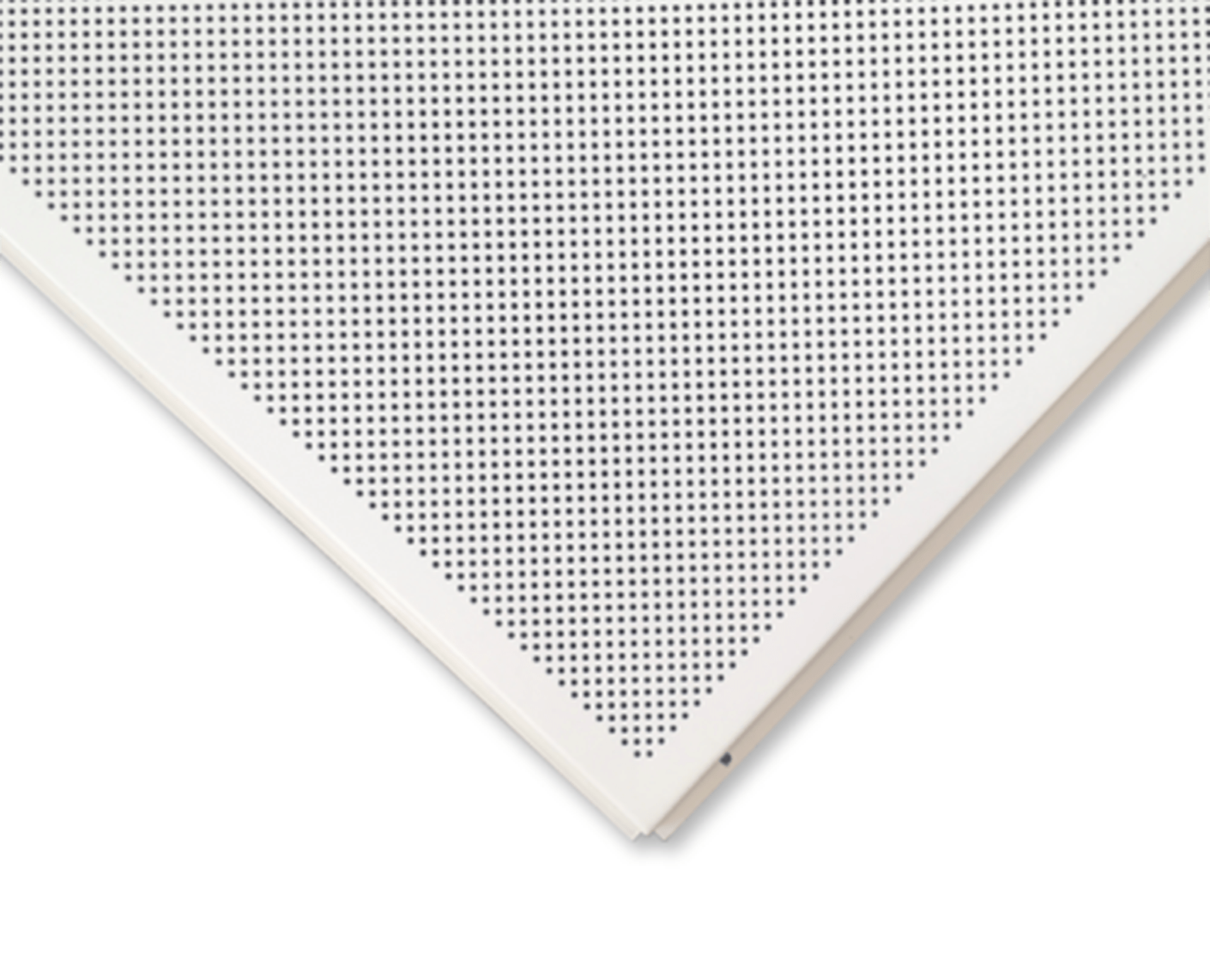

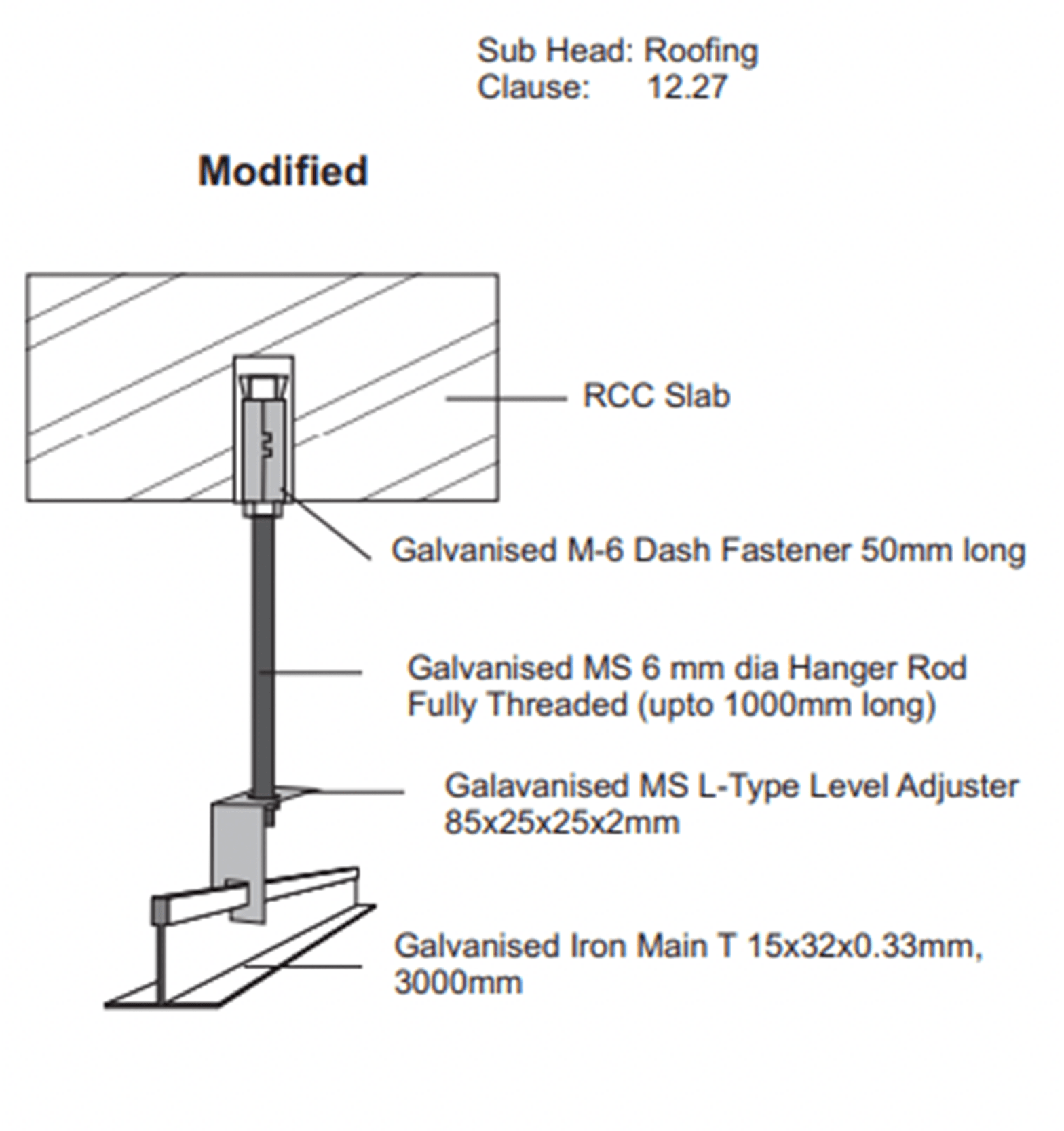

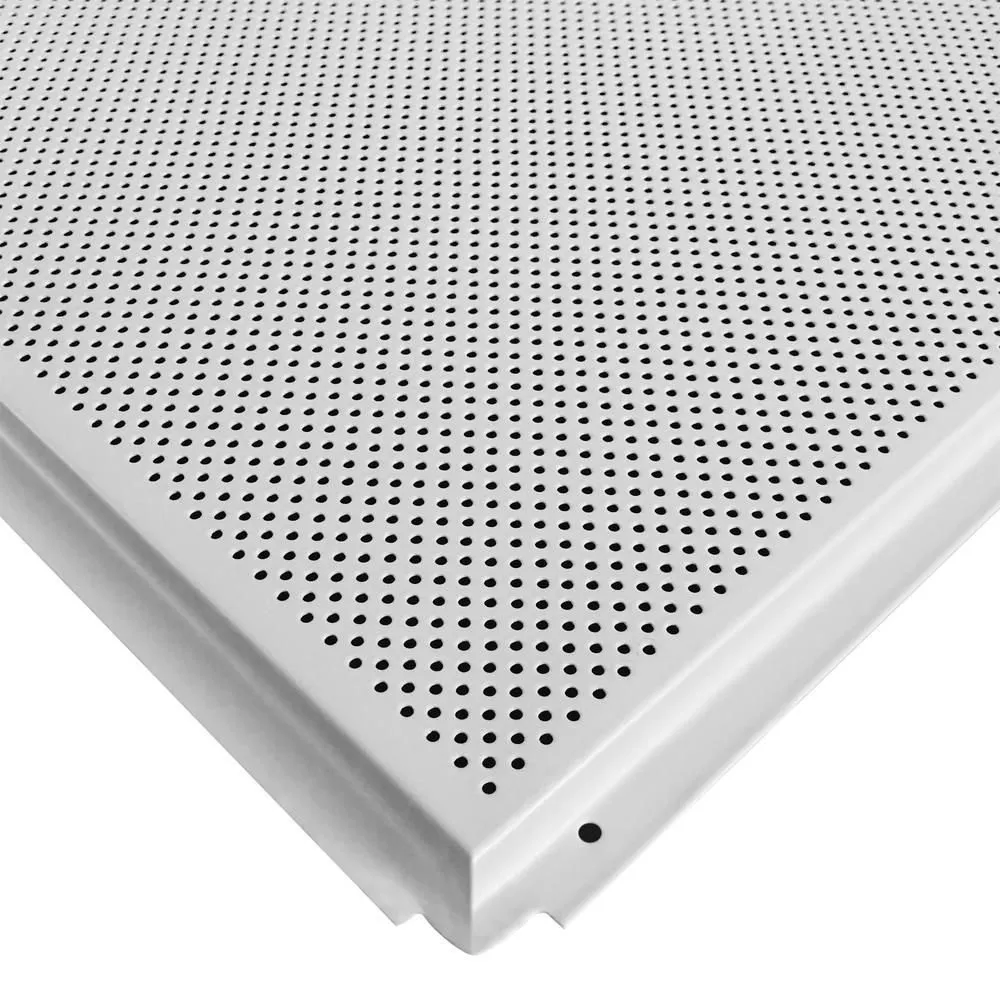

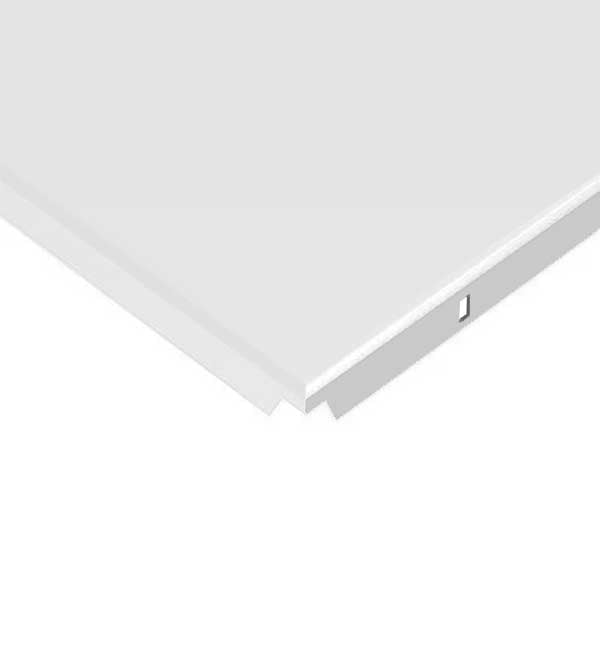

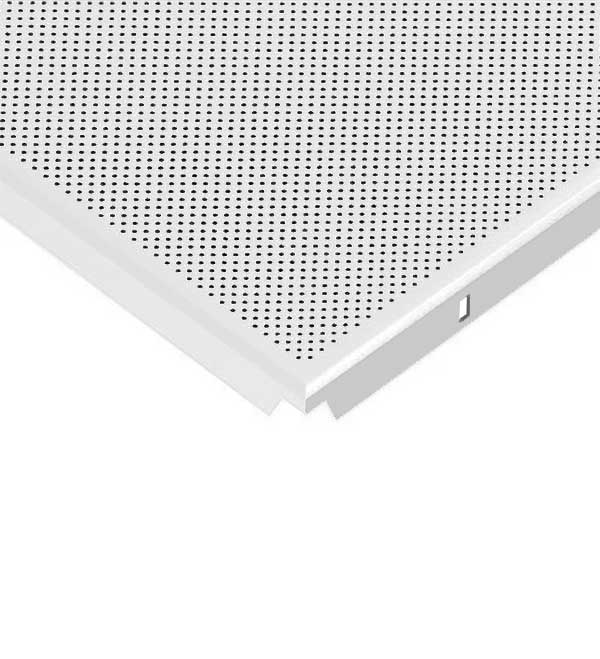

For any construction work, Schedule of Rates plays an important role in pre-construction stage like preparation of estimate & specification of construction materials. Ceiling Tiles products are compliant to specifications as mentioned under DSR.